Fluidizing Powder Coating Contract Metal Finishing

Fluidizing Powder Coating

Prince Manufacturing Fluidizing Process

This method is commonly used for coating metal parts and offers several benefits listed below. Prince Manufacturing offers fluidizing powder coating our of their locations in Monterrey, Mexico and c. Juarez Mexico.

First is an overview of the fluidizing powder coating process:

Preparation of the Substrate:

The first step is to prepare the substrate that will be coated. This involves cleaning the surface to remove any contaminants, such as oil, grease, rust, or old coatings. Proper substrate preparation is essential for ensuring good adhesion of the powder coating.

Preheating:

Some fluidized powder coating systems include a preheating step where the substrate is heated to an appropriate temperature. This helps to improve the adhesion of the powder coating material to the substrate.

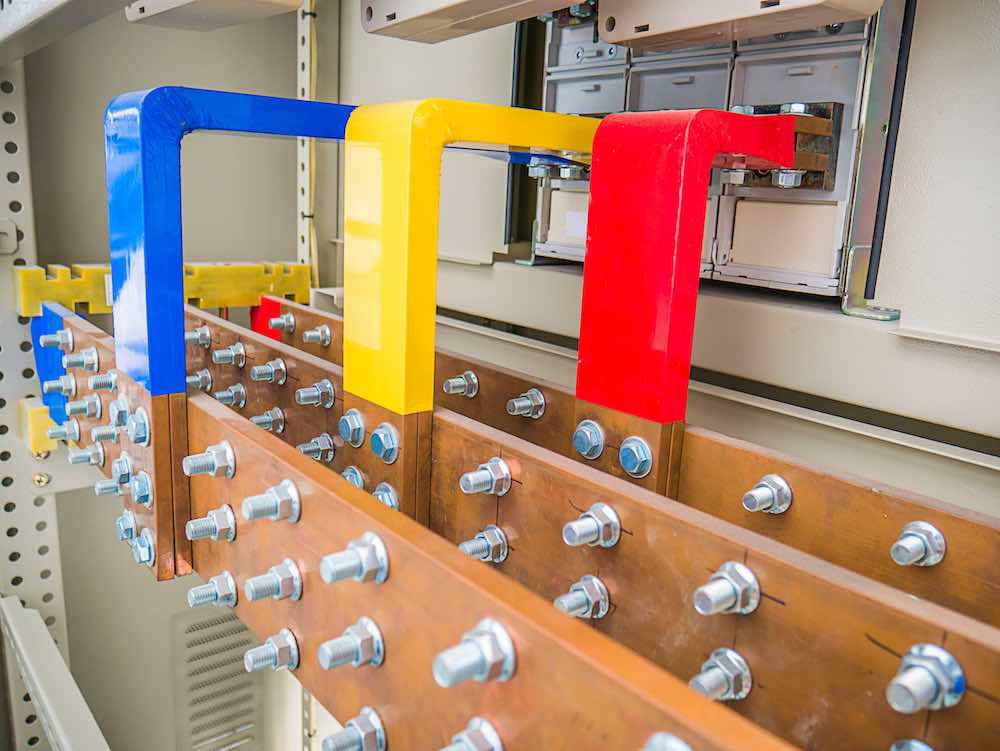

Fluidizing Bed Setup:

The heart of the fluidized powder coating process is the fluidized bed. It consists of a container or chamber filled with the powder coating material. The bottom of the bed is equipped with a porous membrane or diffuser plate. Compressed air is introduced through this plate, which causes the powder coating material to behave like a fluid, creating a fluidized bed.

Application of the Powder Coating:

The preheated substrate is dipped or lowered into the fluidized bed of powder coating material. The fluidized powder particles adhere to the heated surface, creating a thin and even coating. The substrate is typically removed from the bed slowly to ensure an even application.

Excess Material Removal:

After the substrate is coated, it is often allowed to cool briefly. Excess powder coating material that does not adhere to the substrate is removed. This can be done through methods like tapping, blowing, or vibrating, which cause the loose powder particles to fall back into the fluidized bed for reuse.

Curing:

The coated substrate is then transferred to an oven or curing chamber where the powder coating is heated. Curing temperatures and times vary depending on the specific powder coating material being used. The heat causes the powder coating to melt, flow, and form a continuous, durable coating on the substrate.

Cooling and Inspection:

After the curing process is complete, the coated object is allowed to cool. It is then inspected for quality, ensuring that the coating is uniform, adheres well, and meets the desired specifications.

Final Steps (Optional):

Depending on the application, additional steps may be taken, such as post-curing, finishing (e.g., sanding or polishing), and packaging.

The Benefits of Using Prince Manufacturing Fluidizing Powder Coating

Prince Manufacturing provides fluidized powder coating or fluid bed powder coating. It offers several benefits in industrial metal finishing and surface coating processes. Here are some of the critical advantages of using fluidized powder coating offered by one of our four manufacturing facilities:

Uniform Coating Thickness: Fluidized powder coating ensures a consistent and uniform coating thickness on the substrate. This leads to a high-quality finish without variations in appearance or performance.

Even Coverage: The fluidized bed system provides excellent coverage, especially on complex-shaped or intricately designed parts. It can coat surfaces with recesses, corners, and intricate details effectively, ensuring that no areas are missed.

Waste Reduction: Unlike traditional powder coating methods that may result in overspray or wasted powder, fluidized powder coating is more efficient. Excess powder can be collected, sieved, and reused, reducing material waste and saving costs.

Enhanced Durability: Fluidized powder coatings often exhibit superior durability and resistance to corrosion, chemicals, and abrasion. This makes them an ideal choice for applications where a long-lasting finish is essential, such as in the automotive, aerospace, or outdoor furniture industries.

Energy Efficiency: Fluidized powder coating typically requires lower curing temperatures than other methods, which can lead to energy savings. Reduced energy consumption not only lowers operational costs but also makes the process more environmentally friendly.

Color Options: Fluidized powder coating systems offer a wide range of color options. Producers can easily switch between different powder colors to meet customer preferences without the need for complex and time-consuming changeovers.

Quick Curing: Many fluidized powder coating materials cure rapidly, reducing processing time and increasing production efficiency. Quick curing is particularly beneficial for high-volume production environments.

Easy Maintenance: Fluidized bed systems are relatively easy to maintain. They require minimal downtime for cleaning and maintenance, ensuring higher operational uptime and productivity.

Eco-Friendly: Powder coatings, in general, are more environmentally friendly compared to liquid coatings, as they produce fewer volatile organic compounds (VOCs). Fluidized powder coatings contribute to greener manufacturing practices and compliance with environmental regulations.

Adaptability: Fluidized powder coating can be used on various substrates, including metals, plastics, and composites, making it versatile for a wide range of industries and applications.

Cost-Effective: While the initial setup costs for a fluidized powder coating system can be relatively high, the long-term cost-effectiveness is often realized through reduced material waste, less rework, and the ability to coat more parts in less time.

Improved Finish Quality: The smooth and uniform appearance achieved with fluidized powder coating enhances the overall aesthetics of finished products. This can be a crucial factor in industries where the visual appeal of the product is important, such as consumer electronics or architectural coatings.

Prince Manufacturing’s fluidized powder coating service offers numerous advantages, including uniform coverage, reduced waste, durability, energy efficiency, a wide range of color options, quick curing, ease of maintenance, and environmental benefits. These benefits make it popular for manufacturers seeking efficient, high-quality surface finishing solutions.

You can learn more here about fluidizing powder coating services in Monterrey, Mexico.

Whatever your coating requirements, Prince Manufacturing can meet them—even if they are part of a more complex contract manufacturing process. For more information about outsourcing fluidizing powder coating solutions, contact us today.

Back to Paint Coating

Let's Talk. Let us show you.

How will we compress your production cycle time?

Let's Talk. Let us show you.

How will we compress your production cycle time?

Services We also provide

Sign Up Prince Manufacturing Newsletter

How would you like to learn the best manufacturing tactics?

Sign up here. We will share our expertise.

Popular Content

Contact us. Free Consultation about your goals.

Ready to take your business to the next level? Fill out the form below, and let’s discuss achieving your goals together!